Onboard Auto Glow Plug Drivers For Mac

But without voltage PWM compensation the glow is much decreased if the battery goes from 12 to 10 V. This is my modified schematic that works! But still no voltage compensation added. The TO-220 FET is not even cooled but still ice cold! The input current is only 500mA at 12.0V when a normal glow plug is lit fine! Dummy Glow Plug (not included) Kill Switch Charging Schematic for Deluxe Package External Glow Driver Cicuit: This wiring diagram shows how to connect an external source for starting the engine. The kill switch should be marked for external/off and on position. Switch to the on position after starting to use MX9900 with onboard bat-tery.

The Expert Electronics On Board Digital Glow Driver is good insurance against engine flame out. A common cause of flame outs with glow engines is that at idle there's not enough heat produced by the engine, and the glow plug simply goes out. This is an especially common occurrence with inverted mounted engines, 4-strokes, and multi-cylinder engines. The Digital On Board Glow Driver can be programmed to automatically light the glow plug when the throttle is reduced below a preset postilion, preventing those low throttle flame outs and improving the low speed idle characteristics. The unit is easy to install and adjust. A separate 4.8 volt pack is used for power to ignite the glow plug, although a single 1.2V NiCd can be used for weight sensitive situations. Plug the universal connector into a Y-harness plugged into the throttle, or if you're using a computer radio, mix throttle to an unused auxiliary channel and plug the Expert driver into the receiver port of that channel.

Turn on the radio and set the throttle stick to the position that you wish the glow driver to turn on/off, then press the button on the glow driver. This presets the 'on' position into the unit's memory. Any time the throttle is reduced below the preset position, the glow plug will ignite. A 600mAh pack will typically give about an hour of glow power per charge, depending on the glow plug type used. Dimensions are 2-1/4' x 1-7/16' x 5/16' and weight is just 1.4 oz. The unit features polarity protection and an efficient electronic circuitry.

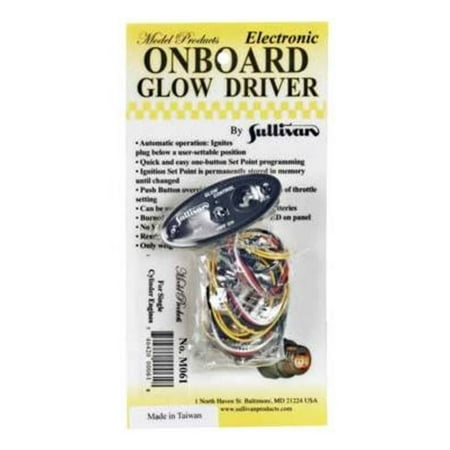

Sullivan Products has a long history of bringing great products for RC planes to the market. One of their latest releases is no different. The latest release is an onboard glow driver that is available in both single and dual engine versions. In the past there have been other glow drivers available that were little more than just a battery and a switch connected to the glow plug on the engine. The Sullivan driver is leaps and bounds above that level. The Sullivan driver can be set so that it is a simple on/off switch if that is what's needed.

But it can also be integrated with your radio system and then programmed to come on with a preset command from the radio receiver. Several possibilities exist with this setup. They range from setting the driver on a separate channel that would allow the unit to be turned on by the flip of a switch when the pilot needed to setting the driver on the throttle channel and having it come on when the throttle is dropped to a specified level. This flexibility will give pilots a lot of options to use this product on. When I was offered the Sullivan Onboard Glow Driver I selected the twin engine version to review.

I had a B-25 that was being reviewed as well, so that gave me a good test bed for this product. The Sullivan Glow Driver comes in a small retail package that consists of a cardboard card with the product shrink wrapped in place on the card. It's obvious that the packaging was aimed at retail displays but that's not an issue as it's more than adequate at getting the product to the user. The instructions for the Glow Driver are printed on the backside of the card that the product is packaged in, so take a little care when removing the driver so that the instructions are legible. At first I thought that the instructions were a bit brief for a product such as this, but after reading through the card I found that they did an excellent job of explaining the installation and operation of this product.

So Sullivan gets a pat on the back for killing two birds with one stone here. Removing the Glow Driver from the packaging reveals the unit itself, which has several sets of wires hanging from it, a separate coil of wire, and two small crimp-on wire ends. If you look at the picture of the unit in comparison to a US quarter you can see that it's not very big at all. On the front of the unit there are several controls and indications. First is a slide 'On/Off' switch that controls the power to the unit. Next is a recessed 'Set' button that is used to program the unit for operation with the plane's radio.

Also recessed is a 'Run' button that is used for manually activating the glow driver. Lastly, a green LED indicator shows when the unit is powered on and operating properly. This is for programming the unit, as well as indicating when a glow plug is burned out.

There are 4 sets of wires that exit from the actual control module for the unit. Those wires are 1) Yellow driver wires. These wires connect to the glow plug of the engine and are terminated with a twist lock connector that attaches to the glow plug. 2) Black ground wire. This wire will attach to the engine to complete the glow circuit.

3) Battery connection. This wire plugs into a separate battery that drives the glow plugs. The battery wire is terminated in a standard connector that will fit most brands of radios. 4) Servo connection. This wire connects to the receiver and is used to control the onboard driver through the radio. The servo wire is also terminated in a standard connector that should fit most major brands of radios.

Lastly is the separate coil of wire. This is used to extend the ground from one engine to the other to complete the glow circuit on both engines. One thing that needs to be pointed out is that the Sullivan driver requires a separate battery pack to drive the glow plugs. The instructions have a very clear warning to NOT connect the glow circuit to the radio's battery pack. While it would work and drive the glow plug(s) it could result in quickly draining the battery resulting in a crash if the battery drops below the voltage needed to operate the receiver and servos.

This needs to be taken into account when planning the installation of the unit so that the control panel isn't located too far away from the battery that will be used to drive the glow plugs. The onboard battery needs to be between 2 v -12 v. The driver will step down the voltage so that the glow plug will operate correctly and not burn out from a larger voltage battery. Installing the Sullivan Onboard Glow Driver can range from a very easy straightforward job all the way to an entailed installation that requires a bit of thought. A single engine installation in a sport plane would be very easy and straightforward. The control panel needs to be mounted on the side of the fuselage, which can be done so that it's mounted close to the receiver and the separate battery pack. Then the wires need to be run to the engine to complete the glow circuit.

But for my twin-engine application there were some problems that immediately showed up as I prepared to install the driver. Those problems were:. The Hangar 9 B-25 is a large plane, and for reasons of balancing the plane the glow driver battery needed to be installed in the nose of the plane. With the battery in place I needed to decide where to place the control panel of the unit. After looking at several different locations on the fuselage I decided to place it in the nose of the plane, directly underneath the cockpit. The main reason why I choose this location was because the battery for the driver was in this location as well and I could keep the wire to the battery short in length when the panel was placed here. The glow driver seems to be designed for a one-piece wing.

With the included wiring the instructions tell you to run a ground wire between the two engines. The H9 B-25 has a two-piece wing so this presented a real problem for wiring the driver to the engines. I needed to find a way to run the wires separately to each wing. One other problem that I noticed here was that the design of the driver unit did not seem to take into account that most twin-engine applications have the engines mounted on the wings.

With a single engine application the entire unit can be installed in the fuselage and not be involved with the wing whatsoever. But in a twin-engine setup the engines are mounted on the wing, and if the control panel is mounted in the fuselage some provision must be made in the wiring so that the wing can be removed from the fuselage. To solve the problem of the ground wire and the removable wing I chose to run two sets of wires (glow plug power and ground) from the control panel, one set going to each engine. This solved the issues of having two wing halves; by running a set of wires to each engine the halves could easily be separated. But this left me with the problem of removing the wings from the fuselage itself.

To solve this I used a power plug and jack (available from Radio Shack) for each set of wires. I simply cut the wires where the wing would join to the fuselage and installed the plugs and jacks. Now when the plane is assembled at the field it?s a simple matter of plugging in the wires for each wing half. Next up is mounting the control panel for the onboard driver in the fuselage. As I said earlier, I choose to mount it under the cockpit of the plane because this is where the driver battery is located, and the panel will be mounted next to the radio power switch.

To mount the panel, first cut a 1-13/16' x 3/4' rectangular hole in the fuselage. The backside of the control panel is removed by taking out two Allen screws that hold it together. Then the front of the unit is installed from the outside of the fuselage, running all of the wires to the inside of the plane.

Once I had the control panel in place the backside is then screwed back in place using the Allen screws through the front of the panel. With the panel in place it was time to extend the wires. Since the battery was located directly behind the onboard driver there was no need to extend the wire for this. Msi rx9250 t128 driver for mac. But this still left me with the glow plug positive connection, glow plug negative connection, and the wire to the receiver that needed to be extended.

For the wire to the receiver I used a standard JR servo extension wire to connect the unit to the receiver. For the glow wires I extended them both to the power jacks that I installed in the fuselage.

In the wings I connected the wires to the power plugs and routed the wiring to each engine nacelle. At the engine I connected each ground wire to an engine-mounting bolt to ensure that I had a good ground. For the glow plug connection I had to remove the twist lock connectors that were provided because they extended outside of the cowl of the B-25.

I soldered two small steel spring clips to the wire and placed heat shrink over it to ensure that the clip didn?t touch the engine and short out the driver. I then attached the clips to the glow plugs. While it sounds pretty complicated it really was a pretty easy installation once I had everything figured out on how I was going to install the unit. Once the unit is in place programming it is really very simple. There are a couple of ways that the unit can be used.

The first is a simple on/off operation. When you are ready to energize the glow plugs turn on the unit with the 'On/Off' switch and then press the 'Run' button. The unit will turn on the glow plug, which will be indicated by a solid green LED. If the glow plug is burned out the LED indicator will flash when it?s turned on. Once you have the engine started simply slide the switch to the 'Off' position to turn off the unit. The second method to use the unit would be controlled with radio.

To do this the unit needs to be programmed. The unit needs to be connected to a channel on the radio that you will use to control the glow driver; most often used will be the throttle channel. For automatic operation, set your throttle stick to the position that you want the plug to come on. Push the white button under the SET hole, and the LED will begin flashing about twice a second for several seconds. Increase throttle on the transmitter while the LED is flashing. This orients the unit for high vs.

Low throttle direction. When the flashing stops, the set point and direction is stored in memory. You can redo this as often as desired. Check the set point by moving the throttle up and down through the set point. The LED will indicate that the plug is on or off. You can change the set point at any time by repeating the above step. If you do not want the unit to come on automatically, move the throttle stick to the lowest position (off) and set the ON position there.

You can also turn the Driver off with the main switch; the throttle servo will still work. Before getting to the flying field the Sullivan Onboard Glow Driver had me sold. I used it when I was breaking in and setting the engines on the B-25. Since I had to start the engines quite a few times during this procedure I figured it would be a great test for the glow driver. Because I was breaking in the engines, and then syncing and setting them, I wanted to be able to turn the glow off to check my idle. So what I did was move the glow driver from the throttle channel to one of the auxiliary channels that were operated with a toggle switch on my radio. This way I could simply turn the glow driver on and off with the flip of a switch on the radio.

With the radio on and the engines fuel up I turned on the switch on the control panel, then a flip of the switch on the radio and the glow plugs should be ready to go. I used my starter on the engine and it immediately fired to life! Using the radio I turned the glow driver off while I let the first engine warm up. When I was ready to start the second engine I again turned on the driver with the radio and applied the starter to the second engine, and it too roared to life. I was really pleased with the way that the Sullivan driver worked. I used a 2500 MaH NiMH 4.8v battery pack to drive the glow plugs in this plane. While I was breaking in and tuning the engines I had to glow plugs on and off for a good portion of an hour as I started the engines over and over during this time.

The battery never gave out during that time and there was always plenty of power to start the engines. For flying the B-25 I changed the radio channel back to the throttle channel, which meant that the glow plugs would be on when the throttle was reduced to the idle position. This would help to improve the reliability of the engines in flight. After the time in my driveway breaking-in the engines the time at the field was almost a let down.

I turned on the radio, turned on the glow driver, and then started the engines. It really was that simple. No mussing and fussing with a glow driver inserted through the cowl to start the engines, and no reaching in to remove the glow driver. I guess that my only real complaint with the Sullivan Onboard Glow Driver would be the amount of work that I had to put into it to install in my application. But once I stop and think about it I will have to concede that it would be really difficult for Sullivan to build a unit that would be ready to go into the large amount of different planes out here. With them shipping the basic unit it is very easy for pilots such as myself to modify the unit for their own applications.

And for single engine planes the installation is very straightforward and simple which should present no problems. For those who have engines with cowls and need an onboard glow driver, or those who need to improve flight operation, the Sullivan Glow Driver can be an invaluable tool. With it's ease of operation from a pre-set throttle stick position pilots won't have to worry any longer when flying. Simply by moving the stick to an idle position their glow plugs will be given power to help improve their low-end reliability. And for those pilots who have an engine enclosed in a cowl the Sullivan driver is a must have. It means no more drilling through cowls to start their planes.

I would say that Sullivan has a hit with this product. Sullivan Products 1 North Haven Street Baltimore, MD 21224 Phone: 410-732-3500 Fax: 410-327-7443. Thanks 2daysoff, RCKen. I purchased a new glow clip from the Toledo show earlier in the month. If I refit the igniter to a plane I will go with that connector or something like RC Ken rigged up. I honestly think the engineers did a good effort in this product, but like everything else in this hobby, it takes a little tweaking and understanding.

I have an FL-70 that I can not bear to put on a good plane. If I find something that will accept the 70, I will put the glow driver on it to make sure that thing is running. I know the glow driver worked when it was working. I like the flickering LED - indicating on time and current usage. Hey, I know these reviews take work - so thanks Ken! Thanks 2daysoff, RCKen. I purchased a new glow clip from the Toledo show earlier in the month.

If I refit the igniter to a plane I will go with that connector or something like RC Ken rigged up. I honestly think the engineers did a good effort in this product, but like everything else in this hobby, it takes a little tweaking and understanding. I have an FL-70 that I can not bear to put on a good plane. If I find something that will accept the 70, I will put the glow driver on it to make sure that thing is running. I know the glow driver worked when it was working.

I like the flickering LED - indicating on time and current usage. Hey, I know these reviews take work - so thanks Ken! I bought a single cylinder unit to operate on my Nosen Trainer with a Saito 1.20 engine. The product states that it works with any 1.2 to 12 volt batteries. I used a 1.2 volt 5000 mah NiCd to light mine.

It did not light. I tried a 700 mah 4.8 volt receiver pack and it barely got warm. Finally it lit up with a 700 mah 9.6 volt Tx pack. I returned it to Sullivan to have it checked out and they said I had a voltage drop at my connector (deans) which I had installed to allow it to be disconnected. I didn't lengthen any wires and used what was provided by Sullivan (#24? Yellow wire to the glow pug connector) and just added the plug.

They said I should use a higher voltage pack or they could replace the yellow wire to the unit with a larger one. The yellow wire is their engineering choice and therefore a defect in design. I refused the change and told them to send it back to me unmolested.

(I'm a bit hard-headed.) It seems to me if you are designing something you should work out the bugs beforehand and if it calls for a larger wire gauge, install it. What are you saving with the smaller wire, a nickel?

All my remote leads are 18 AWG. As a matter of fact, this is what the tech at Sullivan told me I should use.

I guess they don't follow their own advice. I bought a single cylinder unit to operate on my Nosen Trainer with a Saito 1.20 engine.

The product states that it works with any 1.2 to 12 volt batteries. I used a 1.2 volt 5000 mah NiCd to light mine. It did not light. I tried a 700 mah 4.8 volt receiver pack and it barely got warm. Finally it lit up with a 700 mah 9.6 volt Tx pack.

Onboard Auto Glow Plug Drivers For Macbook Pro

I returned it to Sullivan to have it checked out and they said I had a voltage drop at my connector (deans) which I had installed to allow it to be disconnected. I didn't lengthen any wires and used what was provided by Sullivan (#24? Yellow wire to the glow pug connector) and just added the plug. They said I should use a higher voltage pack or they could replace the yellow wire to the unit with a larger one.

Onboard Auto Glow Plug Drivers For Macbook Pro

The yellow wire is their engineering choice and therefore a defect in design. I refused the change and told them to send it back to me unmolested. (I'm a bit hard-headed.) It seems to me if you are designing something you should work out the bugs beforehand and if it calls for a larger wire gauge, install it. What are you saving with the smaller wire, a nickel? All my remote leads are 18 AWG. As a matter of fact, this is what the tech at Sullivan told me I should use. I guess they don't follow their own advice.

The comments, observations and conclusions made in this review are solely with respect to the particular item the editor reviewed and may not apply generally to similar products by the manufacturer. We cannot be responsible for any manufacturer defects in workmanship or other deficiencies in products like the one featured in the review. OR CHECK OUT THESE OTHER GREAT REVIEWS! Photo Summary Ok, enough about Paul because this article is about the MOTIV line of “M-Code” line of motors. The “M-Code” motors come in ma. In late June, 2014, Trinity released the D4 motor to replace the D3.5. Since that time, the D4 has powered cars to 8 ROAR Nat.

I’ve decided to create a series of articles dedicated to helping the average hobbyist get into, or at least consider whether. As an official vehicle of the 2014 Sochi Olympics, Volkswagen built specialized polar edition custom lifted Amarok vehicles u. With its distinctive looks, it is probably safe to say that the J-3 Cub is one of the most recognized and known airplanes in. In June, I tested and wrote about the Traxxas Slash w/ OBA and how much I enjoyed what the Slash offers. It's been a goto veh. RCGF, a Chinese manufacturer of gasoline engines, designs and manufactures engines specifically for 'the RC aircraft market.

RCGF, a Chinese manufacturer of gasoline engines, designs and manufactures engines specifically for the RC aircraft market. When Seagull Models announced that they were going to produce not just a model, but an ARF of the Super Rocket, I just had to. The Flitework Edge 540 is an electric only ARF airframe with a generous wing span of 66.9' and also beautifully dressed up in. Seagull Models introduced this biplane early on in 2015, and SIG mfg. Had a pre-production sample at the Toledo Expo.

ST model brings us a fun aerobatic glider with the H101 Salto. The self-launch electric glider has no bad tendency and will b. RCGF, a Chinese manufacturer of gasoline engines, designs and manufactures engines specifically for 'the RC aircraft market. The new Funky Cub has some really cool attributes, borrowed from scale aircraft, that should add up to make it a great flying.

RCGF, a Chinese manufacturer of gasoline engines, designs and manufactures engines specifically for 'the RC aircraft market. Copyright MH Sub I, LLC dba Internet Brands Copyright © 2001-2018. RCU2 88.99.2.89 0 1 01:12:26 AM EST NC.